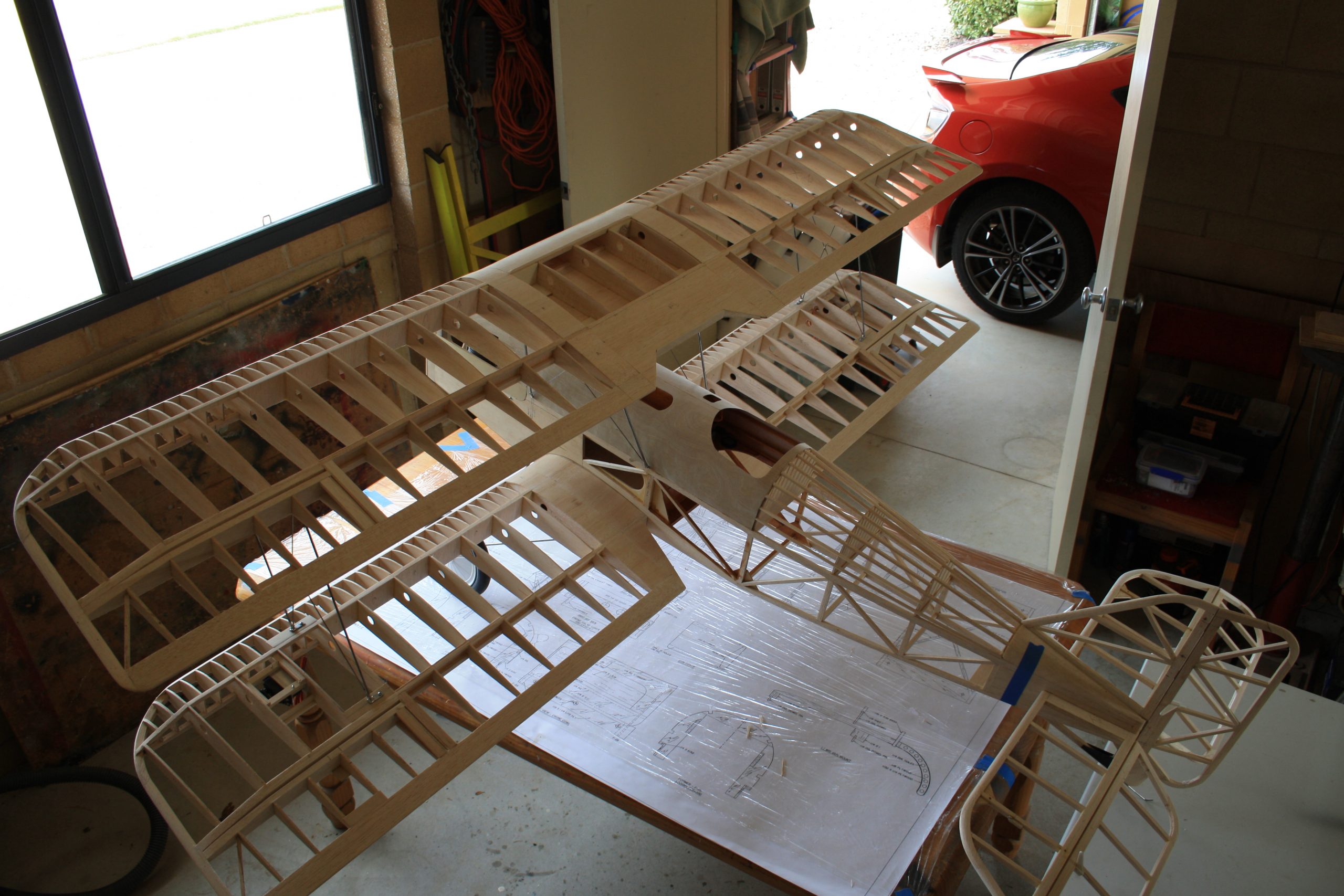

The project started about 2 ½ years ago and was commenced after a less than successful scratch build of another warbird. I decided that building a kit that had a proven history would provide a better platform for a successful build.

After some consideration, and looking at several alternatives, I decided upon the ¼ scale Balsa USA Se5a as my build choice.

I purchase the kit, engine and required radio gear from Rob at Albury RC Models and Hobbies. Rob and Ken offer great service, price and always provide good advice.

The aircraft is powered by a Saito FG40 4 stroke petrol engine which has a great record for reliability and that well known Saito 4 stroke sound, perfect for the Se5a. I chose HiTec metal geared, high voltage servo’s and run a 7.4v Lipo receiver pack.

As I thought it best not to be charging a Lipo inside the model, the engine ignition runs a NiMH battery due to the optimum location making it hard to remove for charging.

When it came time for the scale detail on the model I designed, and 3D printed, all of the instruments and machine guns myself, which took some time, but a task I found very enjoyable.

I also modified the rigging design as the kit called for a hat elastic type rigging that can be easily disconnected when dismantling the aircraft for transportation. Instead I designed a more solid wire that is spring loaded within the airframe but has quick release connectors so the wings can still be removed quickly and efficiently.

The aircraft is covered in Solartex and Koverall and painted. The scheme I chose to finish the aircraft is from the Australian Flying Corp Number 4 Squadron based in the UK during WW1 and weighs in at 22lbs or, for those born after 1970, 9.9kgs

The aircraft is pretty much finished and ready to fly with just the final CofG to be completed and the addition of a scale pilot which I have just ordered from Ren DiLeo at Premier Pilots in the US with delivery in approx. 2 weeks.

For those interested in some history of the Se5a

The S.E.5 (Scout Experimental 5) was designed by Henry Folland, John Kenworthy and Major Frank Goodden of the Royal Aircraft Factory in Farnborough. It was built around the new 150 hp (112 kW) Hispano-Suiza 8, a V8 engine that, while providing excellent performance, was initially underdeveloped and unreliable. The first of three prototypes flew on 22 November 1916. The first two prototypes were lost in crashes (the first killing the chief test pilot at the Royal Aircraft Factory, Major Frank Goodden on 28 January 1917) due to a weakness in their wing design. The third prototype underwent modification before production commenced; the S.E.5 was known in service as an exceptionally strong aircraft which could be dived at very high speed – the squarer wings also gave much improved lateral control at low airspeeds

Like the other significant Royal Aircraft Factory aircraft of the war (B.E.2, F.E.2 and R.E.8) the S.E.5 was inherently stable, making it an excellent gunnery platform, but it was also quite manoeuvrable. It was one of the fastest aircraft of the war at 138 mph (222 km/h), equal at least in speed to the SPAD S XIII and faster than any standard German type of the period. While the S.E.5 was not as agile and effective in a tight dogfight as the Camel it was much easier and safer to fly, particularly for novice pilots. According to “Dodge” Bailey, Chief Test Pilot of the Shuttleworth Collection, it had “somewhat similar handling characteristics to a de Havilland Tiger Moth, but with better excess power”.

S.E.5a

Only 77 original S.E.5 aircraft had been completed prior to production settling upon an improved model, designated as the S.E.5a. The initial models of the S.E.5a differed from late production examples of the S.E.5 only in the type of engine installed – a geared 200 hp Hispano-Suiza 8b, often turning a large clockwise-rotation four-bladed propeller, replacing the 150 hp H.S. 8A model. In total 5,265 S.E.5s were constructed by six manufacturers: Austin Motors (1,650), Air Navigation and Engineering Company (560), Curtiss (1), Martinsyde (258), the Royal Aircraft Factory (200), Vickers (2,164) and Wolseley Motors Limited (431).

Shortly following the American entry into World War I, plans were mooted for several American aircraft manufacturers to commence mass production of aircraft already in service with the Allied powers, one such fighter being the S.E.5. In addition to an order of 38 Austin-built S.E.5a aircraft which were produced in Britain and assigned to the American Expeditionary Force to equip already-deployed US Army squadrons, the US Government issued multiple orders to the Curtiss Aeroplane and Motor Company for the manufacture and delivery of around 1,000 S.E.5s to be produced in the United States. However, only one Curtiss-built aircraft would be completed prior to the end of the conflict, after which demand for the S.E.5 had effectively evaporated, production being quickly halted after a further 56 aircraft were assembled using already-delivered components.

At first, airframe construction outstripped the very limited supply of French-built Hispano-Suiza engines and squadrons earmarked to receive the new fighter had to soldier on with Airco DH 5s and Nieuport 24s until early 1918. The troublesome geared “-8b” model was prone to have serious gear reduction system problems, sometimes with the propeller (and even the entire gearbox on a very few occasions) separating from the engine and airframe in flight, a problem shared with the similarly-powered Sopwith Dolphin. The introduction of the 200 hp (149 kW) Wolseley Viper, a high-compression, direct-drive version of the Hispano-Suiza 8a made under licence by Wolseley Motors Limited, solved the S.E.5a’s engine problems and was promptly adopted as the type’s standard powerplant. A number of aircraft were subsequently converted to a two-seat configuration in order to serve as trainer aircraft.